Always Being Prepared: How Activate Fellows are Building a Resilient Future

October 17, 2022

Photo by Ryan Parker on Unsplash

Resilience, as any entrepreneur knows, is a key attribute of a successful founder. But there is a second reason that resilience is part of the Activate lexicon: it is also a key attribute of the products and solutions our fellows are building.

As the news cycle reminds us daily: every system we rely on, from the energy grid to transportation systems to our food supply, is increasingly vulnerable and must be future-proofed if society is to avoid cascading (not to mention expensive) disasters.

Hurricanes Fiona and Ian, which devastated Puerto Rico and parts of Florida in September, are the 14th and 15th billion-dollar disasters to hit the United States this year alone. As the world prepares for a warming planet and more frequent severe weather events like these, we’re highlighting some of our fellows’ efforts to build products for more resilient infrastructure.

Kevin Kung, Takachar co-founder and CEO.

Defanging Forests, Before Fires Spark

Kevin Kung,

Cohort 2018

Takachar

If you’ve traveled through the thick forests and mountain ranges of the American West, you can appreciate the gargantuan task that land managers, utilities, and other stakeholders face when it comes to mitigating forest fires. As catastrophic fires have become commonplace, it is clear we need more solutions. While prescribed burning is a proven and ancient approach to reducing massive fires, it can’t be used year-round and it becomes more difficult as more people build their homes in fire zones.

While Kevin Kung founded Takachar to provide farmers a way to avoid burning their crop residues and instead turn them into valuable products, the same tech is enabling a new approach to mitigating wildfires by providing a new way to remove highly combustible forest debris and turn that into new products, as well.

.jpg)

Takachar’s prototype of its small-scale, low-cost portable system that can transform agricultural residue into new products.

Jay Schwalbe, Nitricity co-founder and VP of technology

Josh McEnaney, Nitricity co-founder and CTO

Future-Proof Fertilizer

Josh McEnaney and Jay Schwalbe,

Cohort 2020

Nitricity

Earlier this year, a perfect storm of economic factors, extreme weather, pandemic- and war-related supply chain disruptions, inflation, and fuel shortages led to major upheaval in the availability and cost of conventional fertilizer. Those events also thrusted Nitricity into the spotlight.

Conventional fertilizer is not only vulnerable to global supply disruptions like the one we’ve just seen, it’s also responsible for 1.6 percent of global carbon dioxide emissions. Thankfully, Nitricity transformed the way we fix nitrogen by developing technology that turns air, renewable energy, and water into nitrogen fertilizer that can be produced close to farms. This tech goes a long way toward future-proofing fertilizer.

Nitricity’s research field.

Miguel Sierra Aznar, Noble Thermodynamics founder &

Zero-Emission, Dispatchable Power

Miguel Sierra Aznar,

Cohort 2018

Noble Thermodynamics

Redundancy is an important part of any resilient system, and it’s been built into our energy systems so that we can survive major disruptions or react quickly to spikes in energy demand. As we feed more and more wind, solar, geothermal, and other clean energy sources into the energy grid, we’ll also need to rely on legacy power plants to keep energy pumping when high demand or extreme weather forces other forms offline.

By redesigning the combustion engine that power plants currently use to burn natural gas or other fuels to produce electricity, Noble Thermodynamics is able to generate energy while also eliminating carbon dioxide emissions. By deploying this tech across our current power plant infrastructure, Noble is poised to transform over a terawatt of existing polluting dispatchable assets into clean and efficient ones.

Miguel Sierra Aznar & colleague working on Noble Thermodynamics’s closed-loop reciprocating engine.

Marcus Lehmann, CalWave co-founder and CEO

Strong—But Safe—Currents

Marcus Lehmann,

Cohort 2015

CalWave Power Technologies (CalWave)

Wave energy is one of the clean power technologies that have been overshadowed by solar and wind power. But if deployed widely, this renewable energy source could meet a third of global energy demand.

CalWave recently concluded a successful open-ocean demonstration of its wave energy system through a 10-month pilot that subjected the unit to many major Pacific storms—including two that were representative of the largest storms in a typical 10-year period for a utility-scale system—showing that CalWave can produce clean electrons while also weathering some very stormy seas.

Noemi Bonessio, METAseismic founder

Building Shake-Proof Infrastructure

Noemi Bonessio,

Cohort 2020

METAseismic

Harmful vibrations are everywhere, and constantly affect us and our lives. They are the main source of damage for goods during shipping, electronic devices and batteries in vehicles, and buildings during earthquakes. METAseismic develops thin metamaterial liners that can filter out the harmful shaking energy from a vibration source, as shown below—a fast moving shaker jostles two glasses of liquid, and the glass of water on the left rests on a METAseismic liner. These innovative metamaterials are AI-optimized to absorb and dissipate vibrations for a large variety of applications, protect delicate electronics during shipment, increase the resilience of communities to earthquakes and other disasters and, ultimately, save lives

The glass on the left rests on a layer of METAseismic’s metamaterials, which can filter out the harmful shaking energy from a vibration source.

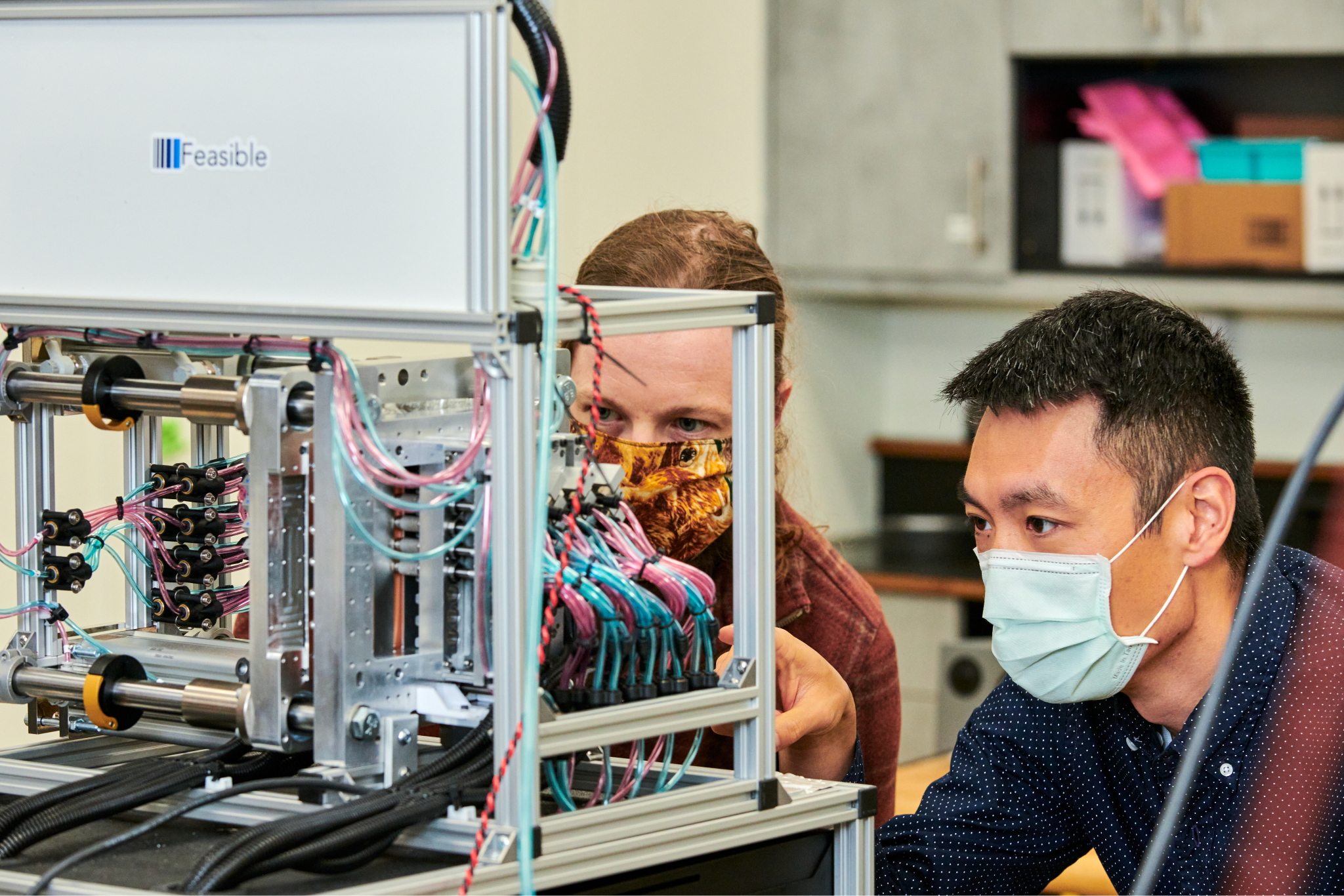

Andrew Hsieh, Liminal co-founder and CEO

Driving Home the Need for Ultra-Sound Batteries

Andrew Hsieh and Barry Van Tassell,

Cohort 2016

Liminal

Barry Van Tassell, Liminal co-founder and chief architect

Honda and LG are building a $4.4 billion plant in the United States to support the astronomical demand for EV batteries. GM and Panasonic are also making big investments in their manufacturing prowess. But let’s not forget the battery recalls that have stymied some early EV rollouts. That’s where Liminal comes in.

Batteries can’t power the clean energy transition if they don’t work as promised, but conventional electrical inspection methods are not up to the task. Liminal uses ultrasound and machine learning to rapidly and non-invasively deliver actionable information to support a thriving, and quality-assured, battery value chain.

Liminal’s technology that uses ultrasound imaging and machine learning analytics for fast, efficient, high-quality inspection and process control in battery manufacturing.

These are just a few of the innovative solutions being dreamed up, tested, and deployed by Activate Fellows, who come to the fellowship with ideas and come out with world-changing technologies. As climate catastrophes strike, and more loom on the horizon, Activate Fellows are drawing on their own resilience as entrepreneurs to ensure a more resilient future for all.